Superfinishing

Here at TS Engineering our superfinishing process is fast becoming a consistently used process within many areas throughout motorsport, engineering and manufacturing sectors.

We can provide a reliable service with fast turnaround times.

Performance

TS Engineerings superfinishing process is set up to refine and polish surfaces to further component performance.

Superfinishing has the benefit of producing a low friction surface that will reduce rolling resistance and contact stresses.

Components

- Crankshafts

- Camshafts

- Ring and Pinion

- Gearbox internals

- Transmission Gears and assorted components

- Driveshaft couplings and universal joints

- Rack and pinion steering components

- Torque converter components

- Clutch hardware

Motorsport

We are currently providing a reliable service with fast turnaround times for all areas of motorsport within the UK and Europe that include:

- Sports car and endurance racing

- Historic racing

- British touring car

- Single seaters

- British superbike/superstock/supersport

- Moto2 and Moto3

- British MX

- Track day customers

Superfinishing benefits

With this engineered finish we can provide a surface that will give the following benefits:

Increased Component Life

Reduced wear and increased durability.

Reduced Friction

A proven increase in performance. Increased power efficiency.

Reduced Contact Stress

Cooler operating temperatures.

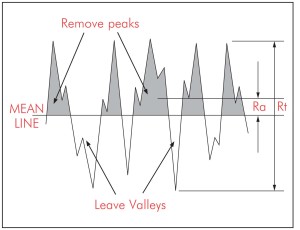

Superfinishing to 0.03 Ra

Dependant upon the quality of the starting finish. Super Accurate tolerances.